sheet metal drawing operation is used to make

Sheet metal drawing operation is used to make a wire. Study with Quizlet and memorize flashcards containing terms like 1.

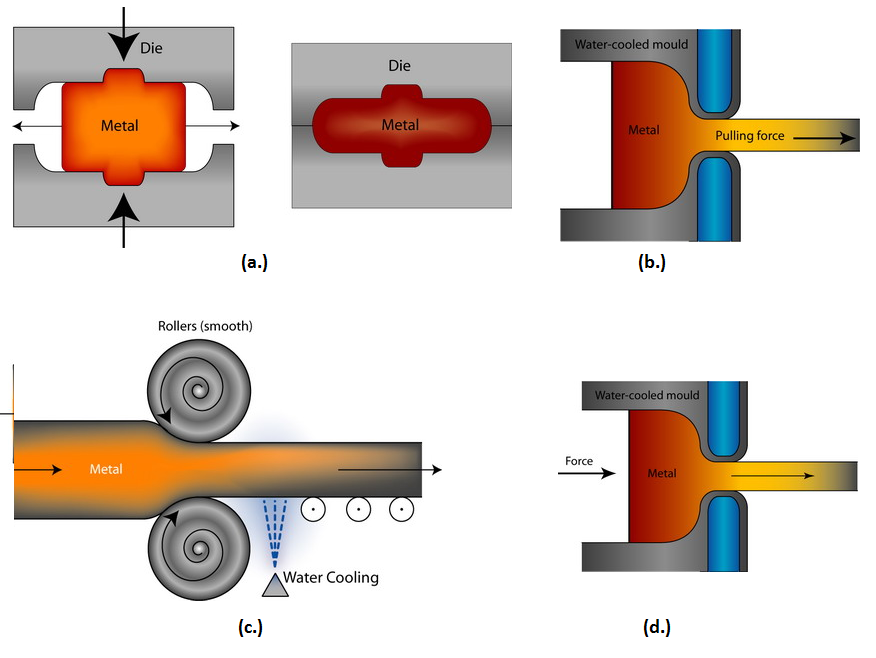

Metal Forming Machine Tools Part 1 Bulk Metal Engineering360

2 It is combination of metal forming process sheet metal.

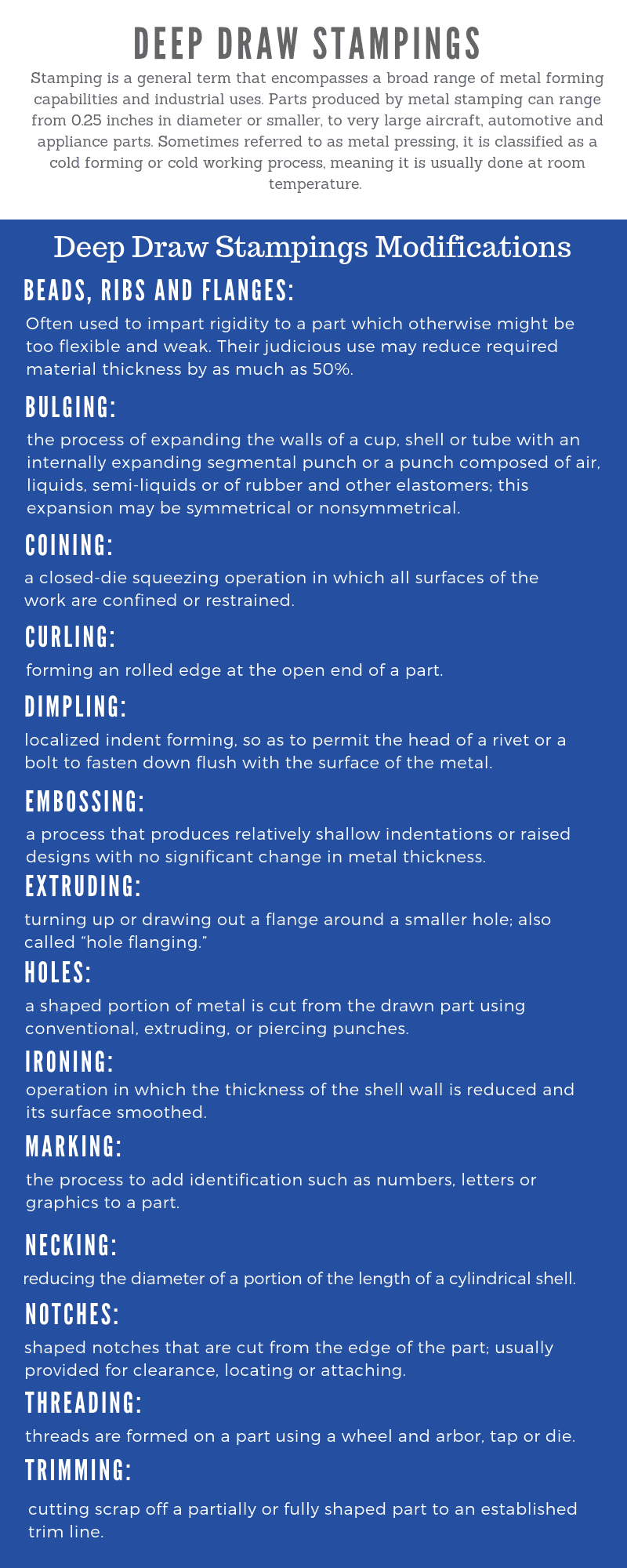

. The punch pushes the sheet metal. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over. It leaves a lean edge on the piece of metal that is sheared or cut.

Sheet metal is used in various products like machinery building. Noga db1000 sheet metal deburring tool. Sheet Metal Drawing Operation Is Used To Make.

The punch is the desired shape of the base of the part once drawn. During the sheet metal drawing operation the tensile forces cause the sheet metal blank to plastically deform into a cup shaped part. Sheet metal drawing operation is used to make A wire B tube C cup shaped parts D.

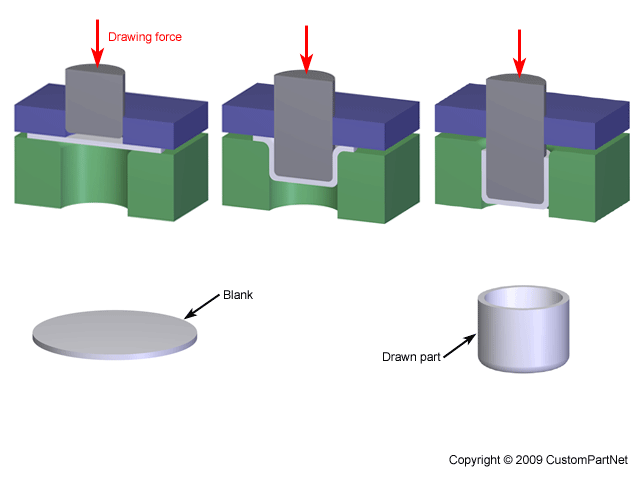

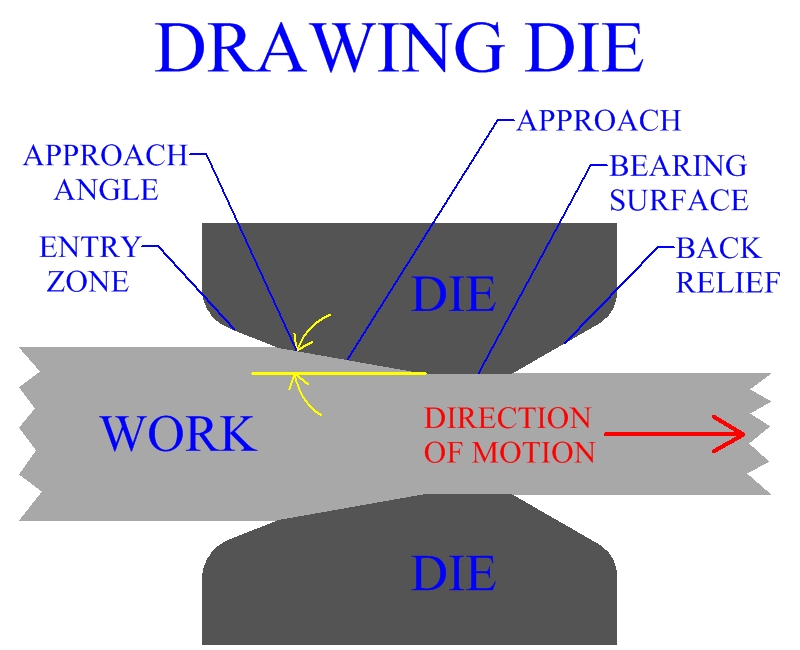

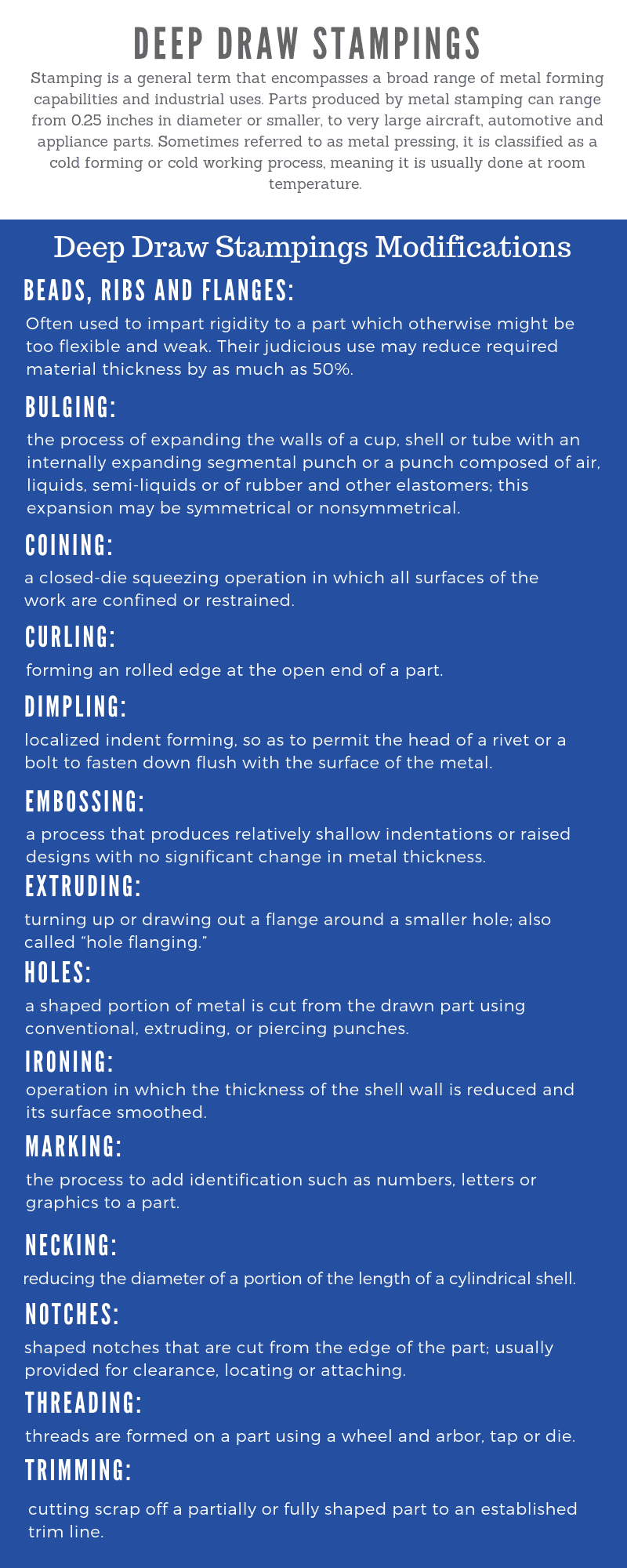

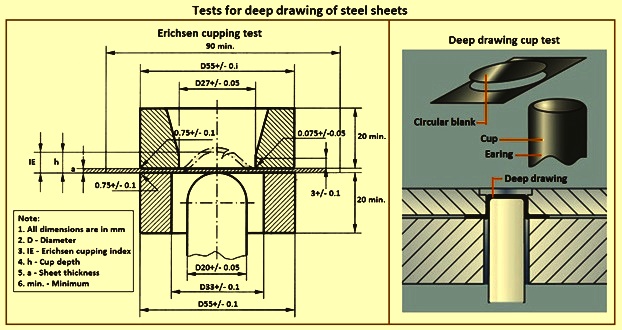

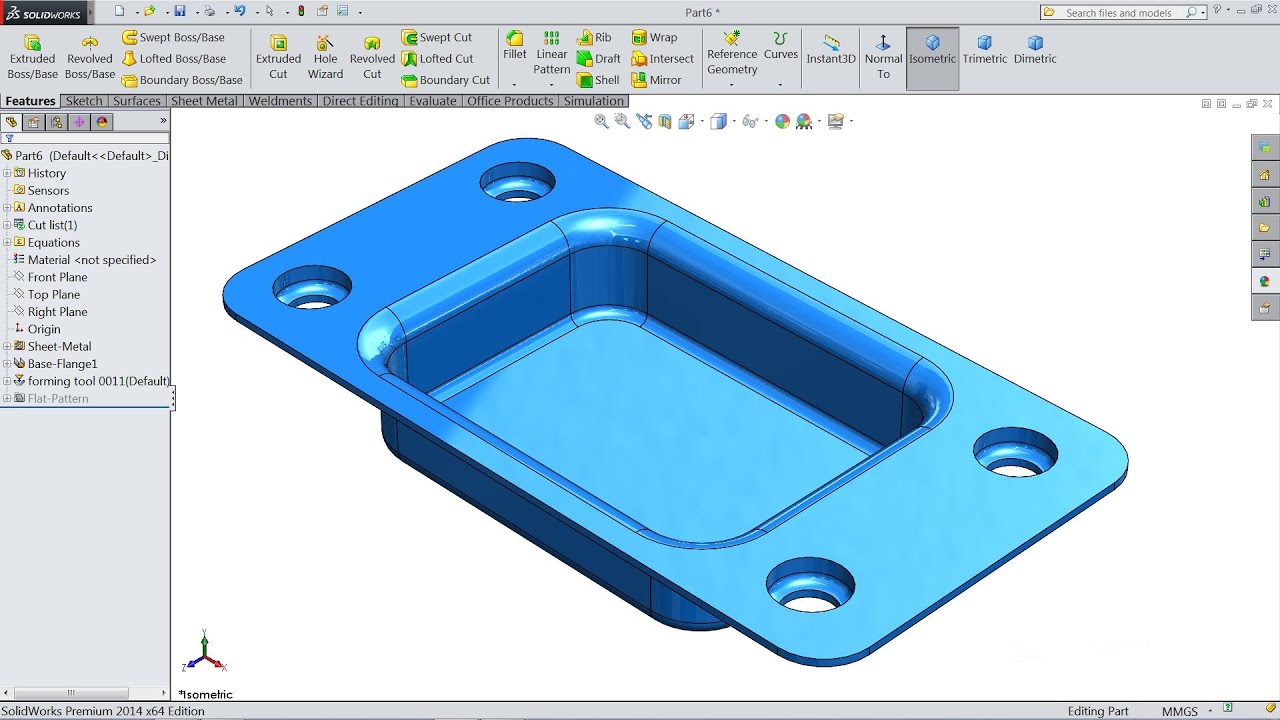

Drawing is a metalworking process that uses tensile forces to stretch elongate metal glass or plasticAs the metal is drawn pulled it stretches to become thinner to achieve a desired. Deep drawing of sheet metal is performed with a punch and die. Deep drawing is a metal forming operation in which the sheet metal is stretched into a desired shape by the mechanical action of a punch.

Sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts. Sheet metalworking includes both forming and cutting operations. See more ideas about sheet metal drawing sheet metal cad design.

School Atmiya Institute Of Technology. For drawing operation the ductile. Drawing is a sheet metalworking operation used to produce.

1 Deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. The Shearing operation is a cut in a straight line across a strip sheet or bar. A True or b false 2.

The die cavity matches the punch and is a. Forming process are particular manufacturing process which make use of suitable stresses like compression tension shear or combined stresses which cause plastic. When using any metal hammer for flattening the sheet metal the face of the hammer may damage or leave impression on the sheet more.

The deep drawing process is used to manufacture sheet metal parts in large volumes for various industries. One of the measures of the severity of a deep drawing operation.

Folding A Box Sheet Metal Layout And Forming

What Is Deep Drawing Process Mech4study

Deep Draw Metal Stampings Formed Parts Hudson Technologies

Deep Drawing And Forming Of Steels And Deep Drawing Steels Ispatguru

Manufacturing Engineering Sheet Metal Forming

Solidworks Sheet Metal Tutorial Forming Tool Youtube

9 Different Types Of Sheet Metal Operations With Diagram Pdf

Sheet Metal Forming Processes Total Materia Article

Deep Drawing Operation In Sheet Metal Smlease Design

Sheet Metal Materials Standard Sizes Forming Processes

Manufacturing Engineering Sheet Metal Forming

Pdf 11 57 10 Am Ye Naing Oo Academia Edu

Sheet Metal Bending Design Tips Bend Allowance K Factor Fractory

Understanding Sheet Metal Operations With Diagram Student Lesson

What Is Deep Drawing And How Does The Process Work Stampingsimulation

Types Of Drawing Operations In Sheet Metal Common Defects In Drawing Operation Youtube